EDI 754 Routing Instructions: Complete Guide to Purpose, Structure & Automation

Last Updated on February 18, 2026 by Tatyana Vandich

Automating EDI 754 Routing Instructions

EDI 754 (Routing Instructions) is the X12 transaction buyers use to communicate who will move the freight, when it should be picked up, and how it must be handled, typically in response to a supplier’s EDI 753 (Request for Routing Instructions). Implemented well, 754 prevents misrouted freight, avoids chargebacks, and accelerates ASN (EDI 856) readiness.

What the EDI 754 is, and How It Fits the Routing Workflow

- Definition: X12 Transaction Set 754 – Routing Instructions. Sent by a buying organization (or its logistics authority) to provide authoritative routing direction – carrier (SCAC), equipment, pickup window, and special handling. It may directly reference the initiating EDI 753.

- Who sends/receives: Typically retailer/buyer → supplier/shipper, sometimes via 3PL/TMS acting as the routing authority.

- When it’s used: After a supplier signals “ready to ship” via EDI 753, the buyer answers with EDI 754. Supplier acknowledges with 997, then uses the instructions to build shipment and generate EDI 856 (ASN).

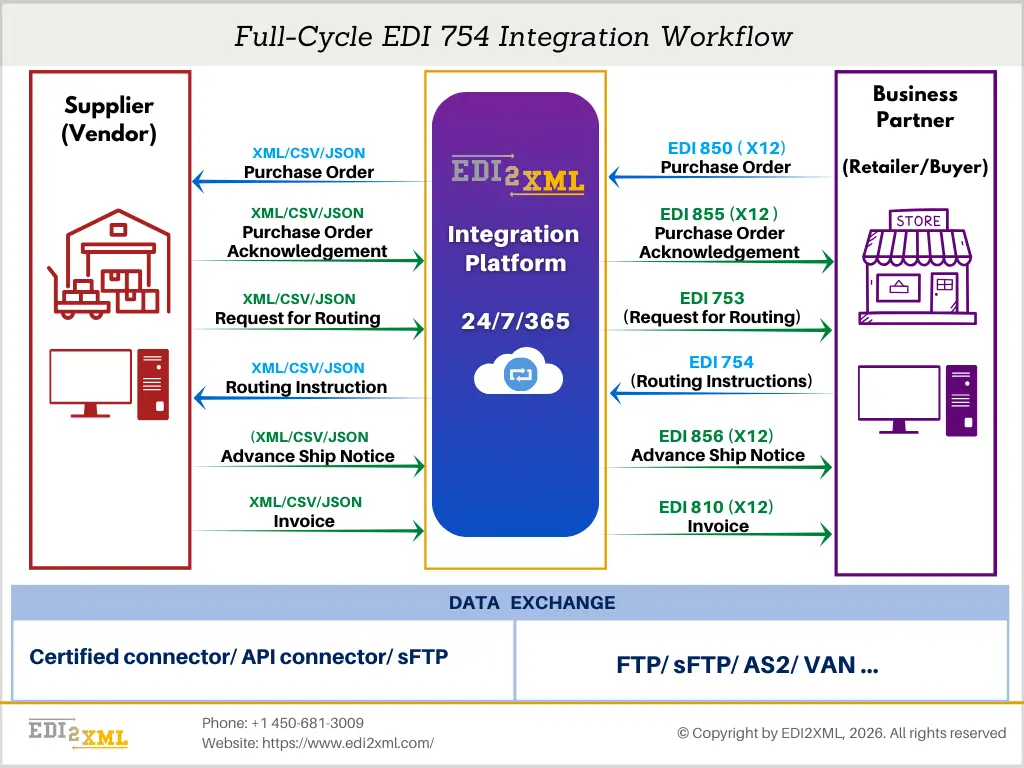

High‑level flow:

PO (EDI 850) → Supplier staging and PO Acknowledgement (EDI855) → Request for routing (EDI 753) → Routing decision → Routing Instructions (EDI 754) → EDI 997 ack → Pick/Pack/Ship → ASN (EDI 856) → Invoice (EDI 810)

Business Value and Outcomes

- Inventory & cost control on the buyer side: EDI 754 centralizes carrier selection and timing, enabling consolidation, appointment scheduling, and lower inbound costs.

- Supplier benefits: Clarity on the authorized carrier and pickup timing reduces back‑and‑forth, prevents rework, and supports on‑time ASN creation.

- Governance & auditability: Routing via EDI 754 leaves a machine‑readable trail tied to purchase orders and loads, useful for claims and performance analytics.

Required Data Elements in an EDI 754

A compliant EDI 754 must contain accurate and validated routing information. Missing or inconsistent data is one of the main causes of processing failures.

Essential information typically included

- Shipment or load reference number

- Ship-from and ship-to addresses

- Requested ship and delivery dates

- Authorized carrier identification

- Routing method and transportation mode

- Reference identifiers such as bill of lading numbers

- Quantity, cartons, or weight data used for routing decisions

These elements allow receiving systems to automatically determine how the shipment must be executed.

The Structure of an EDI 754 (Segments That Actually Matter in Operations)

While exact usage varies by version and trading‑partner guide, these core segments/loops are common in 004010–008010 families:

- ST – Transaction Set Header → control number.

- BGN – Beginning Segment → instruction ID, date/time.

- PER – Contacts (for routing questions).

- G62 – Date/Time (pickup windows, must‑arrive‑by, etc.).

- L11 – References (link to 753 request ID, PO, load/tender ID).

- TD1/TD5 or BLR – Carrier details (SCAC, equipment, service level). Some guides use BLR explicitly for carrier ID and effective date.

- N1/N3/N4 – Parties & locations (Ship‑From, Ship‑To, carrier remit or DC). At least one N1 must identify the ship‑from.

- LX – Line counter for detail loops.

- OID – Order Information Detail (ties routing to PO/lines, qtys, packs).

- PO1/PID/PKG (optional) – Item‑level detail and packaging notes when required.

- SE – Transaction trailer (segment count, control number).

Why this list differs across guides: X12 allows optionality; retailers publish their own implementation conventions. Always reconcile with the partner’s EDI 754 guide. Public examples and dictionaries illustrate the variability.

A Simplified, Readable Example of a EDI 754

Note: Delimiters and exact segment choices vary by partner/version. This is intentionally minimal to illustrate intent; always follow the trading partner’s guide.

ISA*00* *00* *ZZ*SENDERNAME *12*RECEIVERID *YYMMDD*HHMM*|*00403*000000001*0*P*}

GS*RG*SENDERNAME*RECEIVERID*YYYYMMDD*HHMM*1022*X*004030

ST*754*1022

BGN*00*LD000000001*YYYYMMDD

N1*CA*CARRIER NAME*92*CARRIERID

N1*SF*SENDER COMPANY NAME

N3*STREET ADDRESS

N4*CITY*STATE*ZIP*COUNTRY

N1*ST*RECEIVER COMPANY NAME*92*RECEIVERID

N3*STREET ADDRESS

N4*CITY*STATE*ZIP*COUNTRY

LX*1

L11*0000-0*BM

BLR*CARRIERID

OID*00000*0000000*00000-0000-0*CTN*000*L*0000

G62*69*YYYYMMDD

MSI*W*0

SE*16*1022

GE*1*1022

IEA*1*000000001

EDI 753 vs EDI 754

- 753 – Request for Routing Instructions: from supplier; communicates ready‑to‑ship details, requested dates, ship‑from/ship‑to, weights, and references; asks the buyer to decide routing.

- 754 – Routing Instructions: from buyer; authorizes shipment, names the carrier (SCAC), confirms pickup window, and special handling; provides references back to the 753/PO.

Many large retailers (e.g., Amazon, Kohl’s, Dick’s) operate this 753/754 pattern to maintain inbound transportation control.

EDI 754 vs EDI 204

- EDI 204 is a Motor Carrier Load Tender sent directly to carriers to request transportation

- EDI 754 communicates routing rules, not a transportation tender

- The 204 is operational execution; the 754 is compliance and routing control

Incorrectly using a 204 without validated 754 routing instructions can result in routing violations and rejected shipments.

High‑Level Implementation Blueprint (What Your EDI Provider Handles)

Modern EDI routing workflows involve multiple interconnected systems. While companies rely on EDI 754 for routing direction, the operational work behind the scenes is managed by an EDI provider.

1. Integration Touchpoints

Effective EDI 754 processing requires connecting the right systems at the right time, a task usually handled by the EDI integration layer:

- Inbound (Supplier Side): WMS/TMS systems consume the buyer’s 754 to plan dock schedules, prepare inventory, and align carrier-specific shipping requirements. These workflows are documented in WMS implementations.

- Outbound (Buyer Side): Routing authorities (TMS, 3PL, or retailer systems) generate the EDI 754 with the appropriate X12 envelope structure and send it to the supplier. Standards define how the ISA/GS/ST envelopes must be formed.

Why this matters to buyers: You don’t need to manage integrations manually – the EDI provider ensures each system receives complete and compliant routing data.

2. Mapping Essentials (Handled by Your EDI Partner)

Each trading partner may use slightly different qualifiers, references, or segment rules. Your EDI provider standardizes these so you don’t manage them internally:

- Party/Location Qualifiers: N1/N3/N4 loops must consistently identify ship‑from, ship‑to, and carrier parties — a requirement documented in the X12 754 structure.

- Reference Linking (L11): Many partners require the EDI 754 to reference the original EDI 753 or purchase order for traceability.

- Date/Time (G62): Pickup and delivery windows must follow structured formats to avoid ambiguity.

Why this matters: Your EDI partner eliminates mapping inconsistencies that otherwise cause delays or chargebacks.

3. Testing & Certification (Your EDI Provider Ensures This)

Before going live, EDI workflows must be validated end‑to‑end:

- Scenario Testing: SCAC validation, date window checks, ship‑from identification, and other core rules must pass partner tests. These are common validation areas noted in published 754 specs.

- Workflow Testing: The complete lifecycle — 753 → 754 → 997 → 856 — must align with the partner’s transportation workflow. Retailers explicitly define this exchange sequence.

- Envelope Verification: ISA/GS control numbers, functional group (RG), and transaction structure must match X12 standards.

Why this matters: Your EDI provider manages certification with each trading partner so your internal teams don’t have to.

4. Common Production Issues (Your EDI Provider Shields You From Them)

Real-world routing flows can be disrupted by common data errors. EDI providers monitor and prevent them:

- Incorrect carrier codes (SCAC mismatch): 754 relies on correct BLR/TD5 carrier identification.

- Ambiguous pickup/delivery times: Partners require standardized G62 qualifiers, not free‑text notes.

- Missing or incorrect ship‑from: At least one N1 must designate the ship‑from party. This is a mandatory rule in 754 specifications.

- Missing references (L11): Partners often expect the 754 to reference the 753 for routing traceability.

Why this matters: Your EDI provider monitors all exchanges to prevent disruptions before they reach your operations.

5. Security, Compliance & Version Control (Handled by Your EDI Provider)

- Acknowledgments (997): Receipt confirmation is required in 754 workflows, especially in retailer-driven environments. EDI systems track unacknowledged 754s as potential incidents.

- Version Alignment: Partners may require 4010, 4030, 5010, or 8010 variants of the EDI 754.

Why this matters: Your EDI provider ensures all versions and partner requirements stay aligned, so your team doesn’t have to manage technical compliance.

USEFUL: Most companies rely on an EDI integration provider to manage these controls and mapping rules, since maintaining carrier codes, partner‑specific versions, and validation logic in‑house is resource‑heavy.

Entities and Terminology

- ANSI ASC X12 – Standards body and format governing EDI 754.

- SCAC – Standard Carrier Alpha Code in BLR/TD5.

- Routing Authority – The buyer or 3PL/TMS that decides the carrier/routing and issues EDI 754.

- 753 / 754 Pair – Request/Response that governs controlled routing.

Automating EDI 753 and EDI 754 with an Integration Platform

Automation of the 753/754 routing workflow can be achieved in several ways, depending on a company’s systems, resources, and integration strategy.

Where EDI2XML Typically Fits

In practice, solutions such as EDI2XML fit into the automation landscape by offering multiple integration models that support different business needs. A company may choose a fully managed EDI service, where all mapping, translation, communication, partner configuration, testing, and monitoring are handled externally – eliminating the need for on‑premises software or specialized staff.

Others may prefer an HTTP‑based EDI Web Service (REST API) to convert EDI ↔ XML/JSON programmatically, or use a browser‑based EDI Web Portal when they need to exchange EDI without integrating an ERP.

For organizations requiring full internal control, an on‑premises EDI2XML deployment provides local processing using standardized XML schema and EDI conversion engines.

Each method supports automated EDI 753 and EDI 754 workflows; the difference lies in how much of the operational responsibility the business chooses to outsource versus manage internally.

FAQ – EDI 754

FAQ – EDI 754

What is the difference between EDI 753 and EDI 754?

EDI 753 requests routing instructions; 754 provides the approved routing details.

Is 754 always a response to 753?

Often yes, especially in retailer‑controlled freight. However, partners may also issue 754 as direct routing direction tied to POs/loads without a preceding 753 in some programs. Check the partner guide.

What happens after the EDI 754 is received?

Supplier returns EDI 997, books the pickup per instructions, and proceeds toward ASN (EDI 856) reflecting the instructed carrier and windows.

Which industries use EDI 754?

Retail, automotive OEM, 3PL, and any supplier with retailer-controlled inbound freight programs.

Can EDI 754 be fully automated?

Yes. Most organizations generate EDI 754 automatically from ERP, WMS, or TMS systems to ensure accurate routing, compliance with partner routing guides, and reduced manual intervention.

Who sends and who receives an EDI 754 document?

The document is typically sent by a retailer, manufacturer, or shipper to a carrier, 3PL provider, or logistics partner responsible for executing the shipment according to routing requirements.

Is EDI 754 mandatory for all retail supply chains?

No. It is commonly required by large retailers and distribution networks that enforce routing guide compliance. Smaller trading relationships may rely on manual routing instructions instead.

Can an EDI 754 be updated or corrected after transmission?

Yes. If routing conditions change (carrier availability, delivery window adjustments, consolidation changes), a revised EDI 754 can be issued, provided trading partner agreements allow updates.

Conclusion: EDI 754 Transaction Set

EDI 754 is more than a routing memo – it’s the authoritative instruction that synchronizes buyer, supplier, and carrier behavior across systems. If you automate the EDI 753, EDI 754 and EDI 856, you’ll materially reduce detention, misroutes, and ASN defects, while gaining auditable control of inbound freight.

Leave a Reply

Want to join the discussion?Feel free to contribute!